2004 Ram 5.9 Cummins Govenor Pressure Reading 2 Psi at Idle

| Cummins B-Serial Engine | |

|---|---|

six.7 Euro iv / four+ | |

| Overview | |

| Manufacturer | Cummins |

| Also called | 4B/4BT/4BTA 6B/6BT/6BTA ISB QSB |

| Product | 1984–present |

| Layout | |

| Configuration | I-four, I-6 |

| Displacement |

|

| Cylinder bore |

|

| Piston stroke |

|

| Block material | Cast Iron |

| Head material | Cast Fe |

| Valvetrain | Cam-in-cake 2 (B-Serial) or iv (ISB, QSB) Valves/Cylinder |

| Compression ratio | 17.2:ane, 17.3:i, 17.v:1, 19:1 |

| Combustion | |

| Turbocharger | Holset Engineering science (Variable) |

| Fuel organisation | Mutual rail High pressure Directly injection, symmetrical combustion chamber with 7-hole injectors |

| Direction | Bosch Mechanical with Electronic Advance |

| Fuel blazon | Diesel |

| Oil organization | Moisture Sump |

| Cooling system | H2o-Cooled |

| Output | |

| Power output | 53–420 hp (40–313 kW) |

| Torque output | 265–one,075 lb⋅ft (359–1,458 Due north⋅thou) |

| Dimensions | |

| Dry out weight | one,100 lb (499 kg) |

| Emissions | |

| Emissions command technology | Electrical Fuel Control, DPF and EGR |

The Cummins B Series is a family unit of diesel engines produced by American manufacturer Cummins. In product since 1984, the B series engine family is intended for multiple applications on and off-highway, low-cal-duty, and medium-duty. In the automotive industry, it is best known for its apply in school buses, public service buses (about normally the Dennis Dart) in the United kingdom, and Dodge/Ram pickup trucks.

Since its introduction, three generations of the B series engine have been produced, offered in both inline-iv and inline-six configurations in multiple displacements.

General Engine Features [edit]

The B-serial features engine bores machined straight into the cake (rather than the wet liners used on earlier Cummins engines). It was likewise set apart by the use of a shallow one-piece caput, requiring closer tolerances than in other Cummins products.[1] The engine was start manufactured in Rocky Mount, North Carolina, and other plants were later added in Mexico, Brazil, Turkey, and Darlington, UK.[2]

Every Cummins powered Dodge Pickup (since initial production in 1989) has come equipped with a turbocharger. It uses a gear-bulldoze camshaft for actress reliability. Also specified is a deep-skirt engine block and actress-stiff connecting rods. A Holset turbocharger is used. The original B Serial was updated with 24 valves and an electronic engine management system to become the ISB in 1998.

Engine Specifications [edit]

| Model | Cylinders | Fuel | Ability | Torque | Product |

|---|---|---|---|---|---|

| 3.9L | |||||

| 4B | four | Diesel | |||

| 4BT | 105 HP | 265 lb-ft | 1984? - 1998? | ||

| 4BTA | 170 HP | 440 lb-ft | 1998 - ? | ||

| 4.5L | |||||

| ISB | iv | Diesel | 185 HP | ||

| QSB | |||||

| 5.9L | |||||

| 6B | 6 | Diesel | |||

| 6BT | 160 HP | 400 lb-ft | 1984? - 1998 | ||

| 6BTA | |||||

| ISB | 1998 - 2007 | ||||

| 6.7L | |||||

| ISB | 6 | Diesel | 2007 - Present | ||

| B6.7N? | Natural Gas | ||||

B Engine [edit]

three.9L [edit]

The 3.9L 4B/4BT/4BTA Cummins is categorized under the B Engine family alongside the 5.9L 6B/6BT/6BTA Cummins diesel engines. The 3.9L is an inline four-cylinder naturally aspirated (4B) or turbodiesel (4BT/4BTA) that was pop for many footstep van applications, including breadstuff vans and other commercial vehicles. Additionally it has seen broad usage in agricultural machinery. It has also gained popularity equally an engine swap into smaller trucks and SUVs.

4B [edit]

The lowest powered, naturally aspirated 3.9L Cummins, the 4B, produces 53 hp (forty kW).[one] This variant is well-nigh ordinarily institute in equipment such as generators and wood chippers.

4BT [edit]

The 4BT is one of two turbocharged variants of the 3.9L B-Series engine. It contains 2 valves per cylinder for a total of 8. The well-nigh mutual output of this variant is 105 horsepower.

4BTA [edit]

The 4BTA is the updated version of the 4BT, also turbocharged, containing iv valves per cylinder for a total of sixteen. The about common output of this variant is 170 horsepower.

5.9L [edit]

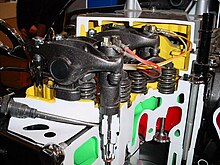

5.9L 6BT Cummins in 1991 Dodge RAM with the valve covers removed exposing the valvetrain

| 5.9L B-Series Cummins |

|---|

| Product: 1984–1998 Camshaft drive: Gear driven Crankshaft: Forged steel, seven master bearings Organisation capacity with filter: 3.five US gal (xiii l; 2.9 imp gal) Cooling system: 6 Us gal (23 l; 5.0 imp gal) coolant System capacity incl heater: 6.5 U.s.a. gal (25 l; 5.iv imp gal) coolant Power output: 160 hp - 230 hp (172 kW) at 2500 rpm Torque: 400 - 440 lb⋅ft (597 N⋅m) at 1600 rpm Pinch ratio: 17.5:i |

The 5.9L Cummins, also known as the "12-Valve" Cummins was the first member of the Cummins B-Serial to be used in a light truck vehicle. The 6BT used Bosch fuel systems, injector, and VE rotary pump and P7100 inline injection pumps. Some early 6BTs were supplied with CAV rotary pumps instead, before the Bosch arrangement became the sole standard. This engine started life in 1984 designed as an agricultural engine, for use in Case farm machinery.[3] [ total commendation needed ] After 1989, the 6BT engine was used in light duty, medium duty and select heavy duty trucks and buses.[ citation needed ] The 6BT engine has recently become very popular for utilise in repowering various vehicles, in the UK they have proven very popular in the Land Rover community, commonly known as the 'skilful' conversion.[ commendation needed ]

6B [edit]

The 6B is the naturally aspirated version of the 6BT with the power output of between 150 to 173 hp and with the compression ratio of 19:1.There were no automotive 6B engines.

6BT [edit]

Actualization in the 1989–1998 Dodge Ram pickup truck, it became a popular culling to the large gasoline V8 engines usually used in full-size pickup trucks, since it produced torque at low engine RPM, and achieved significantly improve fuel mileage. During that time, the Dodge RAM was the but diesel fuel pickup that did not rely on glowplugs for cold weather starting due to indirect fueling.[3]

6BTA [edit]

ISB Engine [edit]

4.5L ISB [edit]

The 4.5L ISB is essentially a 4-cylinder, ii-thirds version of the vi.7L ISB rated at 185 hp (138 kW), used in the New Routemaster, a series hybrid diesel-electric doubledecker bus in London.[four] [5] [6]

5.9L ISB [edit]

| 5.9L ISB Cummins |

|---|

| Product: 1998.5–2007 Camshaft drive: Gear driven Crankshaft: Forged steel, 7 master bearings Organisation capacity with filter: three US gal (11 fifty; 2.v imp gal) Fuel arrangement: Common rail High pressure straight injection, symmetrical combustion chamber Management: Bosch Mechanical with electronic advance Power output: 325 hp (242 kW) at 2900 rpm Torque: 610 lb⋅ft (827 N⋅g) at 1600 rpm Compression ratio: 17.2:1 Emissions command: Electric fuel command |

The 5.9 Fifty; 359.0 cu in (5,883 cc) ISB (Interact Due southystem B) is one of the largest directly-vi engines used for light truck vehicles and school buses, and the improved loftier output 600 version was on the Ward'southward ten Best Engines listing for 2004.

One unusual feature of the ISB is that it is a multi-valve pushrod engine pattern, with 4 valves per cylinder (popularly referred to as the "24-Valve" Cummins). The engine displaces 5.9 L; 359.0 cu in (5,883 cc), with a 102 mm × 120 mm (4.02 in × 4.72 in) cylinder bore and piston stroke. A turbocharger is used to increment the output in the loftier-pinch (17.two:1 in recent versions) diesel. It is an all-iron engine with forged steel connecting rods, an assembled camshaft, and a bandage aluminum intake manifold. The engine is produced in Columbus, Indiana.

The ISB uses electronically controlled Bosch fuel systems, different the 6BT systems which were mechanical. Early ISB engines utilize Bosch injectors and a Bosch VP44 high pressure level pump. Later ISB designs have common rails fuel injection, Bosch injectors, and a Bosch CP3 loftier force per unit area pump.[3]

Dodge Ram ISB [edit]

Midway through model yr 1998, the Contrivance Ram switched from the 6BT to the ISB to see updated emissions requirements. Like other ISB'southward, these engines started out using the Bosch VP44 rotary injection pump. The VP44 setup meant that timing and fuel could be precisely controlled, which led to cleaner emissions. However, VP44 failure rates were college than the older P7100 injection pump. The pinch ratio in these engines was 17.2:1. The 1998–2000 ISB was rated at 215 hp (160 kW; 218 PS) and 420 lb⋅ft (569 Due north⋅m) when equipped with the 47RE automatic transmission. The 1998–2000 ISB was rated at 235 hp (175 kW; 238 PS) and 460 lb⋅ft (624 N⋅m) when equipped with a manual manual. For the 2001-2002 years, a standard output and a high output ISB Cummins engine were offered. The standard output, which was the same as the previous engines was rated to 235 hp (175 kW; 238 PS) and 460 lb⋅ft (624 Northward⋅1000) when equipped with either a manual transmission or automated. The high output ISB was rated at 245 hp (183 kW; 248 PS) and 505 lb⋅ft (685 North⋅m), with only a NV5600 six-speed transmission transmission available. The high output engine was different in a few ways from the standard output engine; information technology had college compression (17.3:1), powdered metallic valve seat inserts, a larger flywheel, the Bosch fuel system was reworked to permit higher fuel flows, and fuel-injection timing was contradistinct.

Dodge Ram ISB CR [edit]

v.nine Cummins Common rail fuel injection organization

For the 2003 model year, the Cummins was introduced with Bosch high pressure common rails fuel injection, again increasing power output. On automatic equipped vehicles, the 47RE was upgraded internally to increase durability and torque capacity, now known every bit the 48RE. The 2003 rating for the Dodge truck was released at 305 hp (227 kW; 309 PS) and 555 lb⋅ft (752 North⋅thou). Midway through the 2004 model yr, the Cummins 600 was introduced, producing 325 hp (242 kW; 330 PS) at 2,900 rpm and 600 lb⋅ft (813 N⋅grand) at ane,600 rpm. This engine was noticeably quieter than the previous engines.[7] [ non-primary source needed ]

6.7 ISB [edit]

| 6.7L ISB Cummins |

|---|

| Production: 2007 – Nowadays Displacement: 6.7 L; 408.2 cu in (vi,690 cc) Bore x stroke: 107 mm × 124 mm (four.21 in × 4.88 in) Max power: 150–400 hp (112–298 kW; 152–406 PS) at 2800 rpm Torque: 610–1,000 lb⋅ft (827–one,356 N⋅m) at ~1600 rpm Compression ratio: 17.3:i Emissions command: EGR and DPF Turbocharger: Holset Engineering (variable) Fuel system: Common rail High pressure directly injection with 7-hole injectors Camshaft drive: Gear driven Crankshaft: Forged steel, 7 primary bearings Oil System capacity with filter: 3 US gal (11 l; two.5 imp gal) |

The 6.7L ISB is the latest version of the B Series. It is currently the largest directly-six engine produced for a light duty truck or school passenger vehicle. It produces 350 hp (261 kW; 355 PS) and 650 lb⋅ft (881 N⋅one thousand) in the 2007.five and newer Dodge 2500/3500 pickup trucks with the Chrysler-congenital six-speed 68RFE automatic transmission built at the Kokomo Transmission plant in Kokomo, Indiana. Engine torque is slightly reduced with the Mercedes G56 6-speed manual transmission at 350 hp (261 kW; 355 PS) and 610 lb⋅ft (827 Due north⋅1000). The 2007 and newer 3500 Cab & Chassis trucks simply get the 305 hp (227 kW; 309 PS) and 610 lb⋅ft (827 N⋅m) version of the B6.7, whether it has the Aisin AS68RC or the Mercedes G56 6-speed manual transmission. As for the 2008 4500/5500 medium duty Chassis Cabs or the Sterling Bullet Trucks, they receive the 350 hp (261 kW; 355 PS) and 610 lb⋅ft (827 N⋅1000) version of the B6.vii, whether information technology has the Aisin AS68RC or the Mercedes G56 half dozen-speed manual transmission. Tardily model 2011 Ram trucks produce 350 hp (261 kW; 355 PS) and 800 lb⋅ft (1,085 N⋅one thousand), with the frazzle brake rating additional from 150 hp (112 kW; 152 PS) to 222 hp (166 kW; 225 PS).[eight]

For 2022 this engine has been updated to produce 400hp and 1000 ft-lb torque.

Information technology is likewise used in the Blueish Bird Vision, Thomas Saf-T-Liner C2, and IC CE school buses

Changes Over the 5.9L ISB [edit]

At that place are many changes over the previous 5.9L ISB for the Dodge truck, the most obvious being the larger displacement. The half dozen.7 ISB had an increase of cylinder bore and piston stroke to 107 mm × 124 mm (iv.21 in × 4.88 in), respectively, thereby giving a displacement of 6.7 L; 408.2 cu in (6,690 cc).[ix] [ full citation needed ]

With the 6.7L ISB came the introduction of the Variable Geometry Turbocharger (VGT). The VGT Turbocharger was introduced to reduce turbo lag by adjusting the vanes by sliding a steel ring in the frazzle housing dependent on engine RPM creating more or less pressure within the exhaust housing and controlling the speed of the turbocharger. Information technology besides works as an integrated exhaust brake system and is all controlled past an electronic actuator on the turbocharger. This VGT system has been an extremely mutual issue with the 6.7L ISB and is typically diagnosed by the loss of the trucks exhaust restriction.[10]

QSB Engine [edit]

5.9 QSB [edit]

The 5.9L QSB (Quantum Organization B) is an off-road, heavy duty version of the ISB. Typically used in marine, agricultural, and construction applications, these engines share many of the same parts equally the ISB and apply the same Bosch fuel system.[ citation needed ]

Fuel System [edit]

Mechanical Injection with Mechanical Timing [edit]

In the earlier models of the Cummins B-Serial Engine, it was almost entirely mechanical including its fuel system. The fuel pump used in these engines was the P7100 injection pump, this pump is driven off the camshaft gear and drives information technology own internal camshaft to inject fuel to the individual injectors.[11] This pump itself was one of the most popular options for fueling for the B-Series Engines because of this simplistic pattern and how reliable it was. The P7100 injection pump also allows for big amounts of fuel to exist delivered into the system with simple tweaking to the system to let for larger injection events.

Mechanical Injection with Electronic Timing [edit]

In the later models of B-Series Engine, the fuel system was switched from mechanical injection and timing to mechanical injection with electronic timing. This was all cheers to Bosch's new VP44 injection pump. The VP44 injection pump is driven at half the camshaft speed and produces fuel pressure level at about 4,500 psi to popular the vertically centered injectors in the engine.[12] These injection pumps need to have constant fuel pressure level behind them of at least 10psi at all times to maintain the priming of the system.[12] If you run these pumps dry it can cause your pump to neglect speedily. The VP44 injection pumps were the first pumps placed in the Cummins engine to take an FPCM. FPCM stands for the fuel pressure control module, and this is responsible for maintaining and controlling the fuel pressure level of the system. All the same, fifty-fifty though this new technology to command fuel pressure level was convenient, it had a major downfall. The problem was that they were unable to be serviced without replacing the entire fuel pump. Some other of import piece of the puzzle that is responsible for the longevity and functionality of the VP44 was the fuel transfer pump mounted on the side of the block side by side to the ECM. This electronically driven vane pump is what supplies that minimum of 10psi to the injection pump so information technology maintains constant fuel pressure every bit well, equally cools itself, and lubricates itself. [12]

Mechanical Injection with Electronic Timing and Common Rail Pressurization [edit]

The well-nigh recent method of fuel injection that is however in employ today is called mutual rail injection. Common rails injection is a completely revolutionary design to fuel injection since a fuel pump is now used to pressurize a rail and and so from at that place sends the fuel to each injector. A major do good of switching over to this fueling system was how it allowed for much less leakage into the cylinders pre and mail ignition. This is all possible since this fuel arrangement operated upwardly of 2600 bar then they are able to set spring tension higher in each injector to allow for more precise fuel injection and timing.[thirteen] Some other benefit of using common rail injection and having i rail pressurized compared to pressurizing each individual injector is that it is more reliable since it allows for more consistent fuel commitment to each injector.[xiv]

References [edit]

- ^ a b Kennett, Pat (June 1986). "The Cummins Beat". TRUCK. London, UK: FF Publishing Ltd: 54–55.

- ^ Kennett, p. 57

- ^ a b c Cummins 5.9-liter and 6.seven-liter inline six-cylinder diesel engines. Allpar.com. Retrieved on 2011-08-04.

- ^ "New Bus for London: Your New Routemaster questions answered". CBS Interactive. Jan 5, 2012. Retrieved 2017-11-27 .

- ^ "LESA44T" (PDF). Wrights Group Limited. 2014. Retrieved 2017-11-27 .

- ^ Wrights Hybrid Wrightbus

- ^ "ISB web". Retrieved 30 Apr 2012.

- ^ 2011 Ram 2500 and 3500 – Capability – Powertrain Archived 2011-02-24 at the Wayback Machine. Ramtrucks.com. Retrieved on 2011-08-04.

- ^ Cummins Engines Archived 2009-04-25 at the Wayback Auto. Everytime.cummins.com. Retrieved on 2011-08-04.

- ^ "Turbo Failure on your half dozen.7L Cummins? Here's what y'all need to know". Dirty Diesel Customs . Retrieved 2019-11-05 .

- ^ "Bosch P7100 Fuel Pump Information". Large Bear Engine Company. 2017-04-10. Retrieved 2020-04-29 .

- ^ a b c "StackPath". world wide web.searchautoparts.com . Retrieved 2020-04-29 .

- ^ "Common Rail Systems". Cummins Inc . Retrieved 2020-04-29 .

- ^ "CP3 injection pump system". Dodge Cummins Diesel Forum . Retrieved 2020-04-29 .

Source: https://en.wikipedia.org/wiki/Cummins_B_Series_engine

0 Response to "2004 Ram 5.9 Cummins Govenor Pressure Reading 2 Psi at Idle"

Post a Comment